Table of Contents

A Simple Guide: Why the Food Industry Uses X-Rays

Most of us think of X-rays as something used by doctors to see inside our bodies. But did you know that X-rays are also used in the food industry? That’s right! X-rays help keep our food safe and high quality. Let’s take a closer look at why the food industry relies on X-rays.(food xray)

Why Are X-Rays Used in Food Processing?

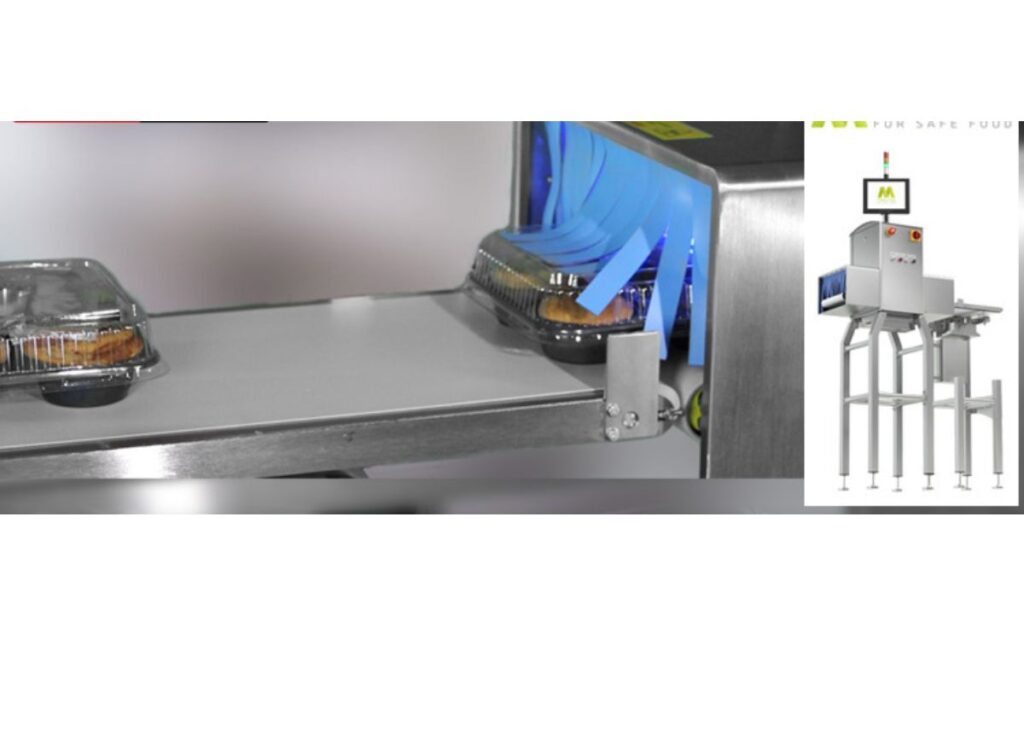

During the processing and packaging of food, it’s crucial to ensure that no harmful or unwanted objects end up in the food we eat. Sometimes, tiny bits of metal, plastic, or other materials can accidentally get into food during production. This can happen due to human error or machinery problems. X-ray machines are used to spot these contaminants.

How Do X-Rays Work in Food Inspection?

X-ray machines in the food industry work similarly to those in hospitals. They send X-ray beams through the food. As the beams pass through, they lose energy when they hit dense materials, like metal or glass. These dense areas show up as dark spots on an image, making it easy to see if there’s something in the food that shouldn’t be there.(food xray)

What Can X-Rays Detect in Food?

X-ray systems can find various unwanted items, such as:(food xray)

- Metal

- Hard and soft plastic

- Glass

- Bone fragments

- Stones or pebbles

- Rubber pieces

This makes X-ray inspection very effective in ensuring that the food we buy is safe to eat.

Food Safety and Quality Assurance

Using X-rays helps food manufacturers comply with important safety regulations, such as:

- Hazard Analysis and Critical Control Points (HACCP)

- Food Safety Modernization Act (FSMA)

- Global Food Safety Initiative (GFSI)

These regulations are designed to protect consumers and ensure that food companies maintain high safety standards.

Real-Life Examples

Food array inspection is crucial because contamination can happen more often than you might think. For example, there was a recall of 2,000 pounds of ground beef because it might have contained pieces of white neoprene. In another case, frozen chicken tenders were found to possibly contain blue dye and plastic pieces. X-ray systems help catch these problems before the food reaches consumers.(food xray)

Comparing X-Rays to Other Inspection Methods

X-ray inspection is more versatile than traditional metal detectors. Here’s a quick comparison:

| Feature | X-Ray Food Inspectors | Food Metal Detectors |

|---|

| What it detects | Metal, glass, plastic, stone, rubber, bone | Metal only (ferrous and non-ferrous) |

| Additional features | Can measure mass, check seal integrity, count pieces | Detects only metal |

| Cost | Higher cost and upkeep | More affordable |

| Packaging | Works with metal containers or packaging | Limited to certain types of packaging |

Benefits of X-Ray Inspection

X-ray technology offers many benefits:

- Detects a wide range of contaminants

- Protects consumers from harmful substances

- Provides accurate and reliable inspection

- Helps maintain high quality and safety standards

- Prevents costly recalls and lawsuits

- Ensures products are properly filled and sealed

Are X-Rays Safe for Food?

Some people worry about radiation, but X-rays used in food inspection are safe. They do not make the food radioactive. The machines are designed with safety features to protect workers from exposure to radiation.

Conclusion

In conclusion, X-ray inspection is a vital tool in the food industry. It helps ensure that our food is safe and high quality by detecting contaminants that other methods might miss. This technology plays a significant role in protecting consumers and maintaining trust in the food we eat.(food xray)

FAQ

Q1: What is X-ray inspection in the food industry?

- A1: X-ray inspection is a process where X-ray machines scan food products to detect foreign objects like metal, plastic, glass, and bone fragments to ensure safety and quality.

Q2: Why do food companies use X-ray inspection?

- A2: Food companies use X-ray inspection to identify and remove contaminants that might accidentally get into food during processing and packaging, ensuring that the food is safe for consumers.

Q3: How do X-ray machines work in food inspection?

- A3: X-ray machines send beams through food products. When these beams hit dense materials, they create dark spots on an image, making it easy to spot contaminants.

Q4: What kinds of contaminants can X-rays detect in food?

- A4: X-ray machines can detect metal, hard and soft plastic, glass, bone fragments, stones, and rubber pieces.

Q5: Is X-ray inspection better than metal detectors?

- A5: Yes, X-ray inspection is more versatile. It can detect a wider range of contaminants, including non-metal objects, whereas metal detectors can only find metal.

Q6: Is it safe to use X-rays on food?

- A6: Yes, using X-rays on food is safe. The X-rays do not make the food radioactive or harmful. The machines also have safety features to protect workers.

Q7: Are there any regulations that require the use of X-ray inspection in the food industry?

- A7: While no specific laws mandate X-ray inspections, many food safety regulations, such as HACCP, FSMA, and GFSI, encourage using effective contamination detection systems, and X-ray inspection is a highly recommended method.

Q8: What are the benefits of using X-ray inspection in the food industry?

- A8: Benefits include detecting a wide range of contaminants, ensuring consumer safety, maintaining high quality and safety standards, preventing costly recalls, and providing accurate and reliable inspection.

Q9: Can X-ray machines inspect food inside metal packaging?

- A9: Yes, X-ray machines can inspect food inside metal containers or packaging, making them more versatile than traditional metal detectors.

Q10: What are some limitations of X-ray inspection?

- A10: X-ray machines may not detect very low-density materials like hair, wood, cardboard, low-density plastics, paper, string, cartilage, and insects. They also have a higher initial cost and upkeep compared to metal detectors.

Q11: How long do X-ray inspection machines typically last?

- A11: X-ray inspection machines typically have a lifespan of 5 to 10 years.

Q12: What is the return on investment for using X-ray inspection systems?

- A12: X-ray inspection systems provide a high return on investment by preventing recalls, ensuring product quality, protecting against lawsuits, and maintaining consumer trust.

Q13: How do X-ray inspection systems help with quality assurance?

- A13: X-ray systems can measure product mass, check for broken or missing items, inspect packaging seals, and verify proper fill levels, ensuring that products meet quality standards.

If you have more questions about X-ray inspection in the food industry, feel free to contact TDI Packsys at 877-834-6750 for more information